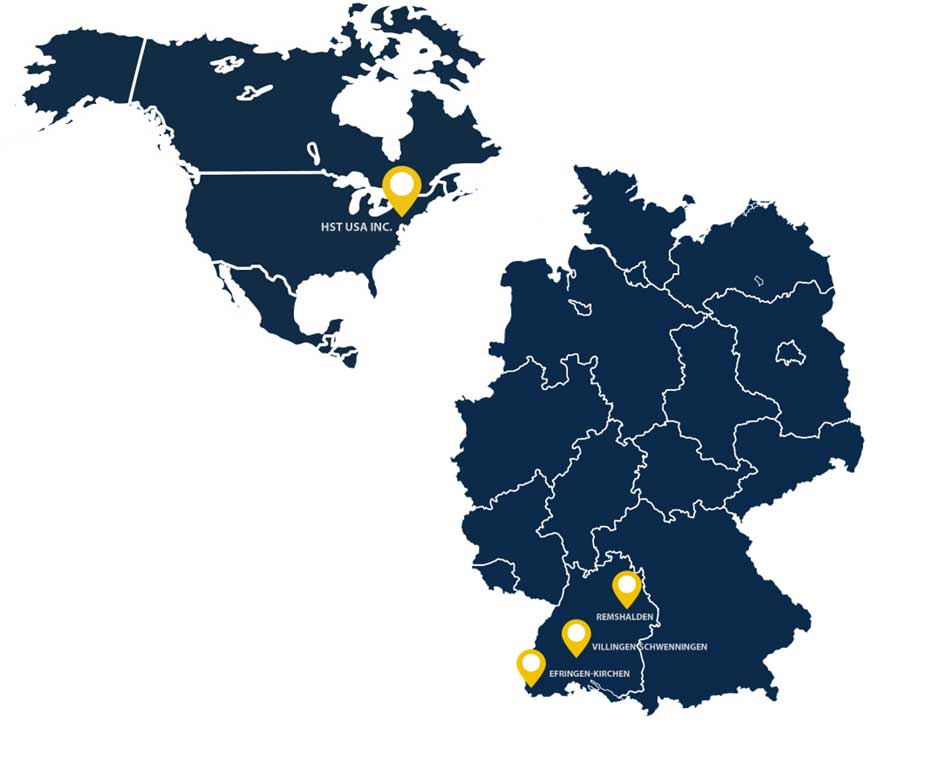

Locations of the HST Group

Head office with production and R&D

in Efringen-Churches

R&D Electronics and software in Remshalden

HST Usa Inc. in Northvale, NJ

History

August 01, 1986 Foundation of HS-Technik - High System Technik GmbH by Hans-Martin Hanke.

First product: Multiple charging station with pulse charging technology for Ni-Cd batteries from 2.4 V to 9.6 V.

First customer: BMW AG.

As a leading medium-sized supplier of screwdriving solutions, we are often the first choice for various leading automotive manufacturers, renowned companies in the aerospace, medical technology, watchmaking, electrical and automation technology sectors - as well as for numerous industrial companies worldwide.

Pioneering spirit, inventiveness and innovation have been the driving force behind our company history of over 35 years.

Mission statement

Our mission explains our intentions as a company and at the same time sets standards by which we measure our decisions.

- Development & manufacture of products with customer benefits that make a decisive difference

- Always being one step ahead technologically

- Rapid adaptation to customer and market requirements

- Sustainable corporate management & environmentally conscious use of resources

- Creating a familiar and modern environment in which employees feel comfortable

Our vision is to produce power tools that change the world of assembly and benefit people, the environment and companies.

Our values describe how we behave.

- Employees: Creating safe workplaces where our employees are inspired to give their best.

- Offer: We offer a portfolio of high-quality products that meet the needs of our customers.

- Customers: Building good relationships that guarantee a lasting partnership and benefits.

- Environment: Responsible use of resources.

- Quality: What we do, we do with perfection.

When developing and manufacturing our high-quality tightening and riveting tools, we therefore rely on no less than:

State-of-the-art technology

Innovation is our passion—this guiding principle has shaped HST for 40 years. As a highly innovative partner, we have made a name for ourselves in the automotive, aviation, and rail vehicle industries in the field of hand-held screwdriving and riveting technology. We combine expertise and competence in high-quality products with maximum customer benefit.

Especially in the field of hand-held cordless tools, HST is constantly setting new standards through innovative developments. Creativity and constant research result in products that meet even the highest demands of the industry.

Quality

From the product to the service. None of our products leave our premises before they have been checked for functionality and accuracy as part of quality control. We use state-of-the-art testing equipment, which is of course calibrated and maintained in accordance with the applicable regulations. We make the current homologation values of our tightening tools available to our customers to download free of charge.

HST is ISO 9001:2015 certified. HST undergoes annual internal and external ISO audits in order to continuously improve and meet the increasing quality requirements of our customers.

Environmental protection

Environmental considerations play a key role in the development of our products. For example, the MV3 series charging stations charge batteries > 95% full. The special charging process enables us to significantly reduce industrial battery waste. HST also offers capacity measuring devices for battery testing. With the help of this process, several thousand batteries can be saved from premature and therefore unnecessary scrapping every year. Environmentally friendly and resource-saving at the same time.

At our site in Efringen-Kirchen, we also rely entirely on renewable energies. For example, we can cover our entire electricity requirements with our solar system.

Career

Take an active part in shaping our future! We inspire and excite employees and customers alike with innovative products and services.

Our history

1986

August 01, 1986 Foundation of HS-Technik - High System Technik GmbH by Hans-Martin Hanke.

First product: Multiple charging station with pulse charging technology for Ni-Cd batteries from 2.4 V to 9.6 V.

First customer: BMW AG.

1987

Start of trading in Hios cordless screwdrivers and rechargeable batteries.

First suppliers of a Hios F-9000 cordless screwdriver with lighting, at that time still with a 6 V flashlight bulb.

HS-Technik adds Hios electric screwdrivers to its product portfolio as a second mainstay.

Development of the first CLT-55 control unit for electric screwdrivers.

1989

2nd generation of charging stations, now batteries up to 12 V can be charged.

Software can be updated at any time with EPROM.

1991

Start of the development of a drilling machine for carbon fiber composites.

1992

Start of robot sales for Janome and Sony, specializing in conversion for cell phone production as tightening and soldering robots.

1993

Development and production of the KMS-2001 capacity measuring device for Ni-Cd batteries.

1994

Relocation of production and administration to larger buildings. Neue Straße 27a + 30.

1995

Presentation of the first LED cordless screwdriver lighting at Motek.

1996

10 years of HS technology!

1997

Relocation of production and administration to own building at the current location in Efringen-Kirchen, Im Martelacker 12.

First own cordless screwdriver WP-xx.

1998

Development and presentation of the CLT-2000 for process-controlled use by various manufacturers of navigation devices.

3rd generation of charging stations.

2000

First white LED lighting for cordless screwdrivers.

2001

15 years of HS-Technik with a big celebration!

2002

2nd generation of the capacitance measuring device now up to 24 V and with 50 programs.

2003

Presentation of the Easy-Posifix system at the Motek in Sinsheim

2004

Development of the Web-Torque screwdriver.

2005

Development of WaveTools.

2006

Introducing the Prog I, the world's first USB-programmable cordless screwdriver.

20 years of HS technology!

2008

Start of development for the BNG-2010 rechargeable blind riveting tool together with BMW AG as development partner.

2009

First delivery of BNG-2010 as a series model to BMW AG.

4th generation of charging stations.

Software update via USB interface.

Presentation of Prog II.

2010

Foundation of the official repair center for HIOS tools in Europe.

2012

Development of the PowerRiv battery-powered blind riveting tool.

Official launch of the PROG-3 series.

2013

PowerRiv 2nd generation.

2014

Development of NutBee and MV3 charging station.

2016

Development TorqBee.

2017

MCU controller development.

2024

Foundation and establishment of HST USA, Inc. for the targeted support and further development of our activities on the US market.

Today

As a leading medium-sized supplier of screwdriving solutions, we are often the first choice for various leading automotive manufacturers, renowned companies in the aerospace, medical technology, watchmaking, electrical, and automation industries—as well as for numerous industrial companies worldwide—when it comes to cordless screwdriving, cordless riveting, and cordless charging technology.

A pioneering spirit, inventiveness, and innovation have been the driving forces behind our 40-year company history.