For guaranteed coffee enjoyment around the clock!

Coffee machines—what would the morning be without them? At least for those who depend on enjoyment and a little caffeine. Whether in the kitchen at home, in a café, or at a coffee-to-go point, the machines must reliably serve up delicious brown coffee for a long time.

Precision and repeatability are equally important in the assembly of coffee machine manufacturers.

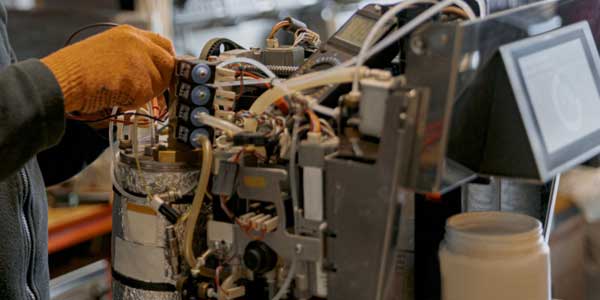

More complex than some people think – the inner workings of a fully automatic machine (Image: Kostiantyn / Adobe Stock)

When it comes to screw connections, everyone has probably encountered challenges at some point that took hours, days, or even months to solve.

Common causes:

- Direct screw connections in sheet metal

- Screw connections in soft materials (e.g., aluminum)

- Grounding screw connections

- Grooved connections in plastic

- Accessibility of the screw location

- Ergonomics in the workplace (screwing process / reaction torques)

- Low torque applications

- Vacuum picking and screw feeding

Intelligent screwdriving technology solutions offer valuable opportunities to monitor and analyze the screwdriving process. Deviations from the expected process are detected directly during screw assembly, ideally avoiding rework and scrap.

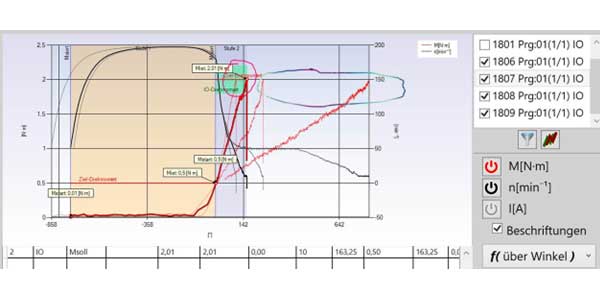

Behavior of different screw connections on a component with analysis options for an EC screw system

Ideally, the screwdriving process should be evaluated at the prototype stage using suitable sensors to measure torque, angle of rotation, and force, in order to ensure that the design and the actual process deliver the same results under assembly conditions. The actual screwdriving strategy and the respective tightening torque/monitoring angle are also defined at this stage.

Screw systems are then adjusted on special testing equipment and measuring sensors and tested for their capability.

Simple testing of a screwdriver on a static torque sensor and screwdriver simulator

Every screw connection is different and requires its own "screw connection strategy."

Screwing into a finished metric thread presents different challenges than screwing directly into sheet metal. Whether screwing into steel, aluminum, or plastic, each type has its own "correct" speed and its own characteristics that must be taken into account when setting up the screwdriving system and during the final quality inspection.

Handy cordless EC screwdrivers for monitored and documentable screwdriving

Accessibility for screwdriving tools in coffee machines, some of which are very complex and compact, repeatedly confronts users with the decision of how to execute a critical connection safely and with repeatable accuracy in series production.

Handy, hand-held screwdriving tools that are as small as possible have a clear advantage. And if they still can't reach the screw, special drive units make every challenge possible. These are designed specifically for the respective tool model.

Special drives and tools for confined spaces

Speaking of small – are you familiar with screw sizes below M2? Low torque applications represent a unique area of screw technology with specific requirements. Many strategies and general knowledge of screw fastening and measurement, as commonly known and used for torques above 1 Nm, no longer apply here.

Suitable low-torque screwdriving and measuring techniques are required here. Repeatable screwdriving and torque measurement starts at just 0.005 Nm. With such small screw connections, the provision of screws and the elimination of all external influences become crucial issues. Measuring sensors in the tools guarantee meaningful repeatability and tolerance. Vacuum solutions are used internally or externally on the tool to pick up the tiny screws. Suitable devices hold the tool stable on the application without any disruptive influences.

Low Torque Tightening – High-precision screw fastening of the smallest connections with integrated vacuum picking

One more word on ergonomics and employee health. Handheld EC screwdriving tools almost always have a reaction torque that is transferred to the worker, especially at the end of a screwdriving operation.

Limit values apply to different tool shapes (rod shape, pistol shape, angle shape). If these limit values are exceeded, tools must be supported. Depending on the workplace situation, there are various options to choose from. Regardless of which technical implementation is chosen, torque supports are not an expensive, necessary nice-to-have, but rather a concrete occupational safety measure and an essential component of product quality and employee satisfaction.

Improved ergonomics, fewer absences due to illness in screw assembly

In short, every good morning coffee is the result of the passion of coffee machine manufacturers, a high level of technical expertise, and modern, safe production processes.

HST not only supports this with globally proven screwdriving and measurement technology, but also with 40 years of experience in a wide range of industries and thousands of customer applications.