SOP - Shut-Off PLUS - why a shut-off wrench with a mechanical clutch has a high-precision torque reaction sensor installed.

Industrially used shut-off wrenches, whether corded, air-powered or battery-powered, can be found in their thousands on assembly lines all over the world. They are robust, durable and offer comparatively high shut-off precision for the set torque.

The mechanical cut-off clutch offers the technical advantage that the torque can be applied to the bolted connection at high speeds.

In high-frequency assembly processes, e.g. in the automotive industry, every tenth of a second counts and therefore the highest possible speeds are required for screwing processes.

Typically, however, shut-off wrenches with a mechanical clutch have an effective variable, but not a real control variable, such as angle of rotation or measured torque value, as is the case with EC wrenches. The shut-off screwdriver with clutch reaches its limits, particularly in the case of tight tolerance requirements in the screwdriving application. In the case of safety-critical screw connections in accordance with Class A, VDI/VDE 2862 sheets 1+2, a shut-off screwdriver is not permitted.

In EC screwdriving systems, high-resolution torque sensors and angle encoders control the screw tightening to the most precise final tightening value. Multi-stage tightening strategies and, as a rule, significantly slower speeds in the final tightening phase make this possible. However, this is usually at the expense of tightening time. High repeat accuracy and speed are rarely compatible in screwdriving technology.

This means that there are two main types of dynamic screwdriving tools when it comes to the procurement of screwdriving technology:

On the one hand, there is the simple, robust and fast shut-off screwdriver with a mechanical clutch, but without any real monitoring variables relating to the screwdriving process - on the other hand, there is EC screwdriving technology with static or rotating torque sensors, which guarantees minimum torque tolerances for each individual screwdriving application by means of multi-stage parameterization, flexible speed and high-resolution angle monitoring - at the expense of speed or screwdriving times.

Precision and monitoring OR simple and fast? Or would you prefer everything in one tool?

Yes, the solution is shut-off screwdriver with reaction sensor and angle monitoring

Shut Off PLUS!

The SOP combines both technologies in one tool.

What are the advantages and different areas of application?

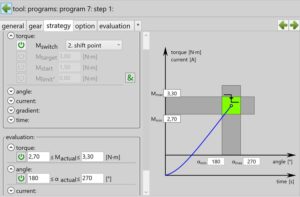

a) Screwing at high speed and tolerances of less than or equal to 10 percent depending on the screw joint, with complete monitoring of specified torque and angle of rotation limits, including safety-critical screw joints in accordance with VDI/VDE 2862 sheets 1+2.

b) One tool covers several torque programs, e.g. the highest torque works mechanically shut-off and fast, all lower torques (up to 99) are screwed as EC screwdriving system.

c) The tool is used as a fully-fledged EC screwdriving system with up to 99 programs. The mechanical shut-off clutch ensures that the tool will never reach more than the torque set in the clutch, even in the event of damage. An important safety feature in working environments or screw-folding applications where a defined torque must never be exceeded.

d) Money and time saved! Shut-off screwdrivers are subject to shorter test cycles due to the lack of internal monitoring options (VDI/VDE 2645 Sheet 2). With SOP, the test cycles can be significantly extended under certain circumstances, as the internal torque sensor clearly measures the shut-off torque for every tightening operation and every tightening result is documented in the tool (up to 150,000 results/curves). In concrete terms, this means greater safety in the event of tool damage or wear to the mechanical shut-off clutch.

Do you often have to make decisions? Then try out this hybrid technology, which has been in use for many years in a wide range of industries worldwide, before making a purchase.