TorqBee - EC Screwdriver - For excellent assembly processes

TorqBee

EC Screwdriver

EC screwdrivers are revolutionizing assembly processes by delivering precise and reliable results. These tools are specifically designed for industrial applications that demand the highest levels of accuracy and performance. Using advanced technology, our solutions ensure precise torque control, providing process reliability in any fastening environment.

The ergonomic design of our industrial cordless screwdrivers not only increases efficiency, but also improves comfort for specialist personnel. The choice between bar or pistol shape enables flexible adaptation to different working conditions. Users also benefit from improved ergonomics, which leads to less fatigue in the long term.

| Feature | TorqBee ECO series | TorqBee EC series | TorqBee EC² series |

|---|---|---|---|

| Sensors | Torque reaction sensor | Rotating torque and angle sensor | Rotating torque and rotation angle sensor + redundant torque reaction sensor |

| Machine capability | According to VDI/VDE 2645 - Sheet 2 ±7% Cm > 2.00 | Cmk > 1.67 | According to VDI/VDE 2645 - Sheet 2 ±7% Cm > 2.00 | Cmk > 1.67 | According to VDI/VDE 2645 - Sheet 2 ±7% Cm > 2.00 | Cmk > 1.67 |

| Programming | 6 levels: Torque, current, angle of rotation, speed, time | 6 levels: Torque, current, angle of rotation, speed, time | 6 levels: Torque, current, angle, speed, time |

| Handle vibration alarm | Yes | Yes | Yes |

| LED indicator light | Multicolored all around | Multicolored all around | Multicolored all around |

| Intelligent battery management | Yes | Yes | Yes |

| Brushless high-performance motor | Yes | Yes | Yes |

| Display of the screwing results | Yes | Yes | Yes |

| Recuperation (energy recovery) | Yes (extends the battery life) | Yes (extends the battery life) | Yes (extends the battery life) |

| Maximum ergonomics | Yes | Yes | Yes |

| LED lighting for the tightening environment | Yes | Yes | Yes |

| Updates can be carried out via USB | Yes | Yes | Yes |

| OLED display | Yes | Yes | Yes |

| Screw counter | Yes | Yes | Yes |

| Count memory function | Yes | Yes | Yes |

| Number of individual programs | 100 | 100 | 100 |

| Storage capacity | At least 150,000 tightening results incl. torque and rotation angle curve | At least 150,000 tightening results incl. torque and rotation angle curve | At least 150,000 tightening results incl. torque and angle curve |

| IO/NIO evaluation of the switch-off result | Yes, including checking the mechanical shut-off clutch | Yes | Yes |

| Programmable screwing strategies | Not specified | All common screwdriving strategies | All common screwdriving strategies |

| Redundancy in accordance with VDI/VDE 2862 | Not specified | Not specified | Torque reaction sensor as redundancy |

| Optional features | Barcode scanner & WLAN | Barcode scanner & WLAN | Barcode scanner & WLAN |

What is an EC screwdriver and why it is indispensable for your company

An EC screwdriver, also known as an electronically commutated screwdriver, is an advanced solution in modern screwdriving technology. These tools are characterized by their ability to precisely control torque and ensure consistently high quality with every fastening. The integration of this technology can significantly optimize the assembly process and increase productivity.

EC screwdriving systems not only record the assembly process, but also analyze and document it, which offers greater process reliability compared to compressed air-operated systems.

In addition to their technical precision, EC screwdrivers offer ergonomic benefits that are specially tailored to industrial requirements. With a selection of models such as the cordless rod screwdriver or the cordless screwdriver gun, skilled workers can work flexibly - even under demanding conditions. This reduces staff fatigue and at the same time increases efficiency in the workflow.

The advantages of bar and pistol-shaped industrial cordless screwdrivers

Rod and pistol shapes offer specific advantages that optimize their use in assembly. A key advantage is the ergonomic design of both models, which makes them easy to handle. The choice between a cordless screwdriver in rod form or as a cordless screwdriver gun offers flexibility for different working environments. This variety makes it easier for specialist personnel to work efficiently even under challenging conditions.

In addition to ergonomics, the precise controllability of the torque plays a decisive role. Thanks to their special design, both shapes help to ensure consistently high screw connections - a must for any demanding industrial application with high quality requirements for assembly processes. EC screwdrivers are specialized tools for the precise fastening and removal of screws, ensuring torque accuracy and preventing damage to components.

Torque accuracy: The key to torque process reliability

In modern screwdriving technology, torque accuracy is a decisive factor for smooth production. It ensures that every screw connection is made with the exact tightening torque required, which not only improves quality assurance but also minimizes rework. Our EC screwdrivers offer you maximum reliability and are specially designed to ensure precise torques in demanding applications.

In addition to the technical advantages, the ergonomic design of our tools also contributes to efficiency. With options such as cordless rod screwdrivers or cordless screwdriver guns, you can react flexibly to different working conditions and thus optimize your processes. The right choice of tool ensures that your specialist staff work more efficiently while reducing fatigue - a plus point for any business.

Energy-efficient solutions thanks to recuperation technology

With the innovative recuperation technology, you can rely on sustainable energy savings in your assembly processes. This technology enables the recovery of energy that is released during the screwdriving process, thereby significantly reducing power consumption. In combination with our EC screwdrivers, you not only benefit from an extended battery life, but also from lower operating costs.

In addition to energy recovery, this technology offers further benefits for your company: Integration into existing systems is straightforward and immediately increases your efficiency. It also ensures that our industrial cordless screwdrivers work optimally - even when used intensively over long periods of time. So you can be sure that every bolting task is carried out reliably.

Smart control systems for optimal screwdriving strategies

The implementation of smart control systems in modern manufacturing is revolutionizing the way bolting processes are carried out. These systems allow you to monitor and adjust every bolting task with the utmost precision. The use of advanced sensor technology ensures that all parameters are optimally set - from the speed to the final tightening force.

With the help of these intelligent technologies, you can not only make your processes more efficient, but also extend the service life of your tools. Real-time monitoring allows you to adapt immediately to changing conditions or requirements in the production process. This ensures that every work step runs smoothly and potential sources of error are detected at an early stage.

Application diversity: Expanding flexibility in the field of application

With our EC screwdrivers, you can significantly increase the variety of applications in your business. The option to choose between a cordless rod screwdriver and a cordless screwdriver gun offers you maximum adaptability to different working environments. This choice allows your specialist staff to work efficiently even in confined spaces.

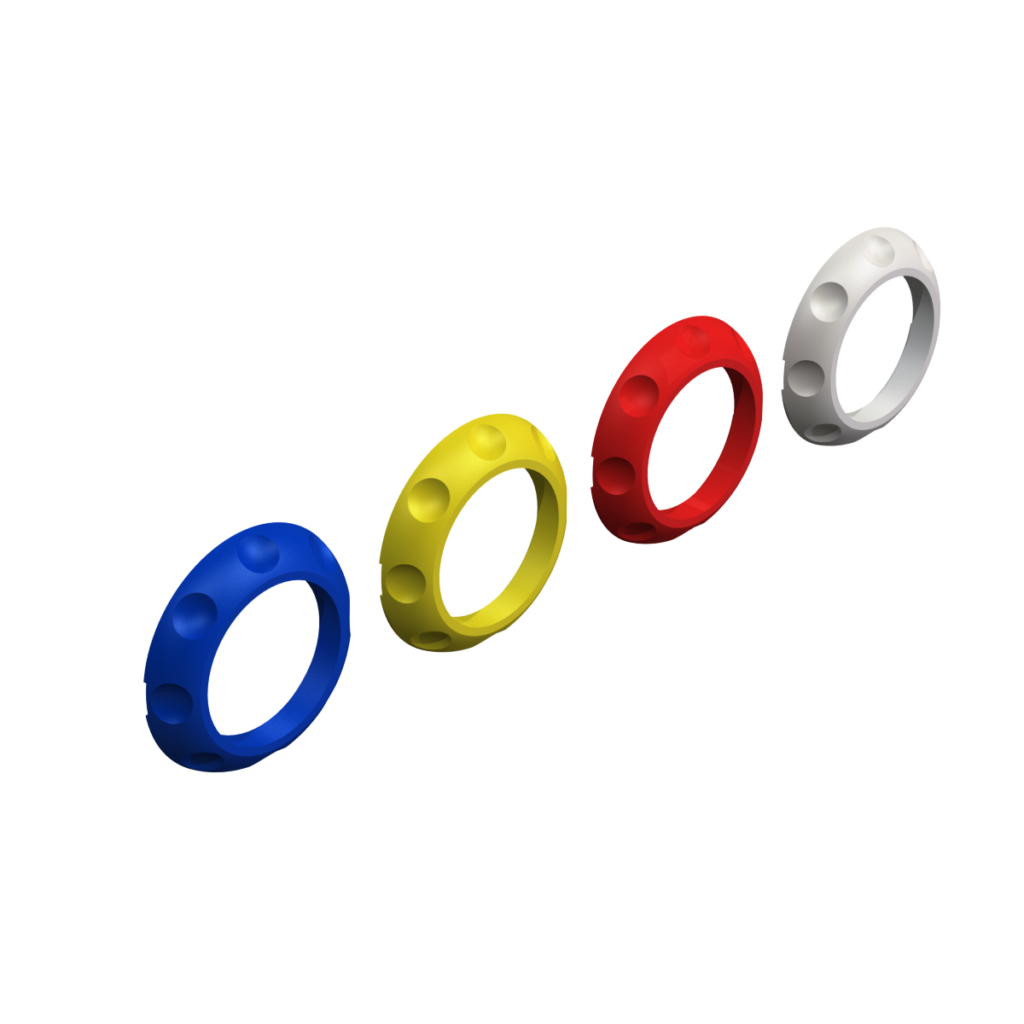

In addition to the design, the accessories also play a decisive role in the flexible use of our tools. An extensive range of attachments enables you to carry out any screwdriving task with precision - whether in the automotive industry or in mechanical engineering. This not only ensures optimum results, but also increases the efficiency of your employees.

Future-proof investments thanks to modular expandability

The modular expandability of EC nutrunners allows you to react flexibly to future requirements. These tools are designed in such a way that they can be easily adapted to changing production conditions. By using a modular system, you can expand your screwdriving technology efficiently and thus save costs in the long term.

In addition to the flexibility in customization, the system enables a quick response to specific customer requests or market changes. The integration of additional functions such as a cordless screwdriver gun or a cordless rod screwdriver is uncomplicated and immediately increases the efficiency of your assembly processes. This keeps you competitive and ensures your long-term success.

Service videos

Operating instructions

TorqBee

Setting the tightening torque for pistol & angle screwdriver

TorqBee

Functionality of the barcode scanner for pistol & angle screwdriver